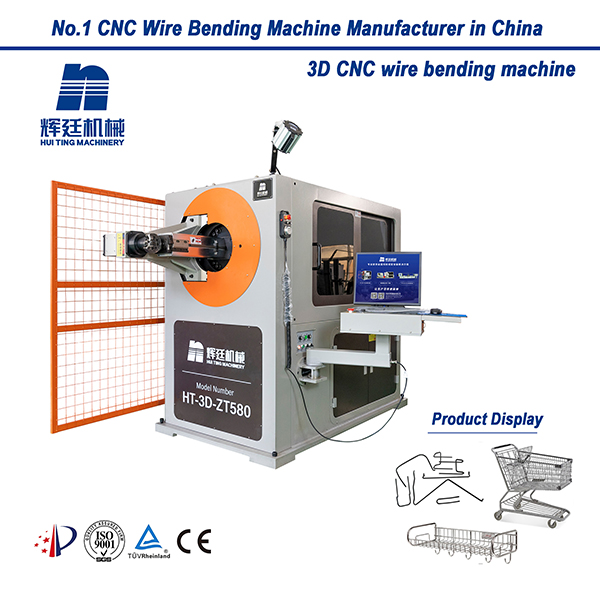

Product Details

Description:

1.Use multi-axis computer control system and imported servo motor, achieving the perfect combination between intelligence and power.

2.Use the computer with interface in Chinese and English(optional),easy operation and accurate positioning.

Achieve both synchronous and isolated operation of motors,ensuring higher lever of automation.

3.Be equipped with precision detection and tracking system, achieving the automatic stop of the machine in case of any unqualified product, thus improving product quality while ensuring the qualification.

4.It is able to modify parameters such as outer diameter and angle of products at any time according to the working condition shown on the display,providing more intuitive operation experience for you.

5.Characterized by reasonable mechanical structure, no line change during turning, fast cutting speed and high stability of angle bending win many national patents and honors.6.Due to the design of the automatic machinery lubrication system, provide the protection for equipment during long time of operation and reduce manual maintenance cost of the equipment.

7.With the intelligent feeding module, ensuring automatic stop of the machine in case of wire wrapping and automatic rack speed acceleration.Thus making production easier and more efficient.

8.Can be used for production of auto seat frames, metal wire hand works,kitchen utensils and table ware brackets,storage cages,supermarket trolleys and shelves and other wire forming products.

Parameters:

Number of axis:5 axes

Wire size: Ø2.0—Ø8.0mm(Tensile strength≦500N)

Number of feeding rollers: 3sets

Power of wire feeding motor:3.8KW

Power of rotation motor:2.7KW

Power of cutter motor:1.0KW

Power of forward-backward motor:1.0KW

Power of sleeve rotation motor:2.0KW

Weight of machine:2800kg

Input power:380V/50HZ/3P

Dimension of machine:2600*2200*2000mm

+852-24221123

+852-24221123

E-mail

E-mail