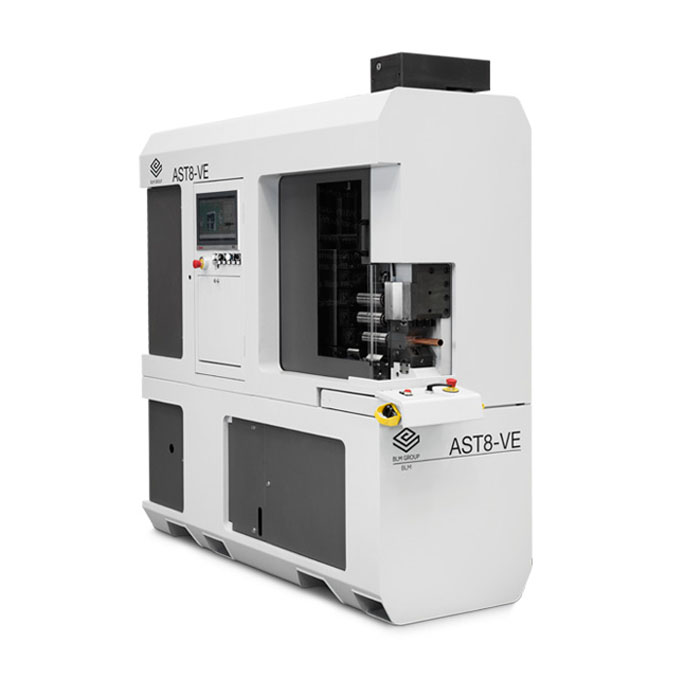

Product Description

CNC Bending Machine for Wire & Tube

C31E is the model with the wider flexibility and it is available in 3 sizes for wire and tube. The innovative eccentric head allows for reduced tube deformation and bending on mandrel or insert with different execution sequence (ex. centered eyelets). It is equipped with a full electric automation system based on a real CNC. The system, with rollers wire guide arm, prevents undesired torsions on wire during bending. Besides OMCG’s legendary reliability and long lasting mechanics, it shares with the latest OMCG CNC benders the new 3D human machine interface software Easy Programming 4 with simulation and anti-collision check.

Technical Data

C31E10 C31E14 C31E18

| Wire diameter (steel/stainless steel) | 3-10 mm (0.12-0.39 in ) | 5-14 mm (0.20-0.55 in) | 6-18 mm (0.24-0.71 in) |

| Tube Ø x thickness (steel/stainless steel) max. | 10 x 2 mm (0.39 x 0.08 in) | 14 x 2 mm (0.55 x 0.08 in) | 16 x 3 mm (0.63 x 0.12 in) |

| Nominal tensile strength | 600 N/mm2 | 600 N/mm2 | 600 N/mm2 |

| Axes | 5 | 6 | 6 |

| Bending radii (on mandrel) max. | 2 | 2 | 2 |

| Bending radii (on insert) max. | 2 | 2 | 2 |

| Radius change | electric | electric | electric |

| Flat frame side max. length | 760 mm (29.92 in) | 950 mm (37.40 in) | 950 mm (37.40 in) |

| Feeding axis (x) | |||

| Material feed length | 0 to infinite | 0 to infinite | 0 to infinite |

| Feed accuracy | ±0.1 mm (±0.004 in) | ±0.1 mm (±0.004 in) | ±0.1 mm (±0.004 in) |

| Max. speed | 139 m/min (456 ft/min) | 94 m/min (308 ft/min) | 57 m/min (187 ft/min) |

| Bending axis (y) | |||

| Bend accuracy | ±0.2° | ±0.2° | ±0.2° |

| Bending time (90° bend) | 0.4 s | 0.5 s | 0.7 s |

| Bending time (180° bend) | 0.6 s | 0.7 s | 1 s |

| Radius generation | available | available | available |

| Rotation | ±166° | ±180° | ±180° |

| Wire guide arm length | 850 mm (33.46 in) | 1000 mm (39.37 in) | 1000 mm (39.37 in) |

| Rotating platform axis (z) | |||

| Accuracy | ±0.2° | ±0.2° | ±0.2° |

| Max. rotation angle | ”+180°/-160° | ”+180°/-160° | ”+180°/-160° |

| Max. rotation speed | 424°/s | 290°/s | 190°/s |

| Mandrel bending radius change axis (a) | |||

| Max. stroke | 26 mm (1.02 in) | 48 mm (1.89 in) | 52 mm (2.05 in) |

| Bending center change axis accentric (b) | |||

| Axis rotation | R30 | R40 | R50 |

| Power, dimensions and weight | |||

| Mains electricity* | EU: 400 V 3-ph+N 50 Hz US: 208-480 V 3-ph 60 Hz |

EU: 400 V 3-ph+N 50 Hz US: 208-480 V 3-ph 60 Hz |

EU: 400 V 3-ph+N 50 Hz US: 208-575 V 3-ph 60 Hz |

| Total installed power | 28 kW | 35 kW | 60 kW |

| Required power | 12 kW | 15 kW | 22 kW |

| Average power consumption** | 7 kWh | 8.5 kWh | 14 kWh |

| Compressed air requirements | 90 psi (6 bar) @ 100 Nl/min | 90 psi (6 bar) @ 100 Nl/min | 90 psi (6 bar) @ 100 Nl/min |

| Dimensions (LxWxH), straightener and safety guards included | 5100 x 2640 x 1800 mm (201 x 104 x 71 in) |

5100 x 2640 x 2100 mm (201 x 104 x 83 in) |

6000x2640x2100 mm (236x104x83 in) |

+852-24221123

+852-24221123

E-mail

E-mail